www.medical-devices.tech

05

'23

Written on Modified on

DESKTOP METAL News

DESKTOP HEALTH ANNOUNCES FIRST PATIENTS TREATED WITH FDA-CLEARED CMFLEX™

The first 3D printed regenerative bone graft product cleared by the FDA, CMFlex has now been used in two patient jaw surgeries, an upper and lower, and several dental socket preservation cases.

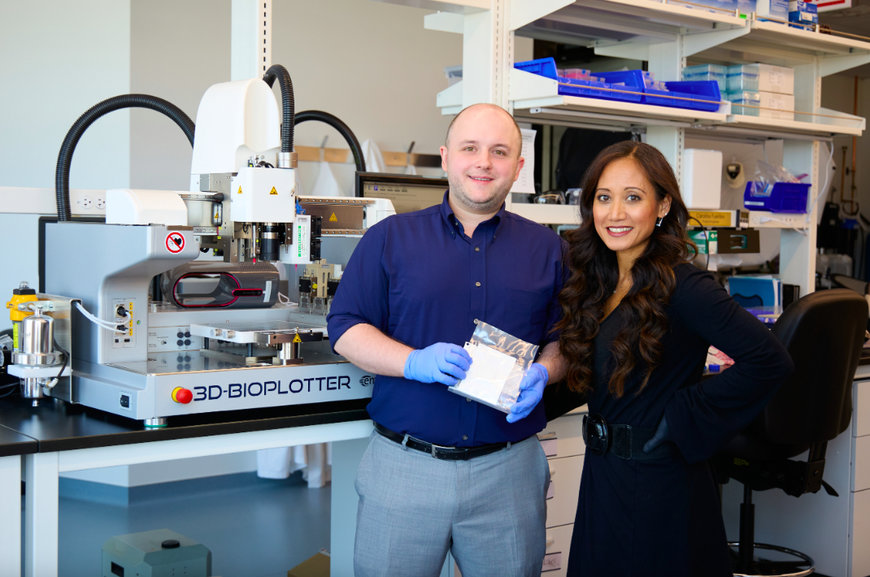

CMFlex™ was co-invented by Dimension Inx co-founders, Dr. Ramille Shah, CSO, Head of R&D, (pictured right) and Dr. Adam Jakus, CTO, Head of Technology Strategy, (pictured left). The duo have been developing the material and product since 2009 on the Desktop Health 3D-Bioplotter®. (Photo: Business Wire)

Desktop Health announced the first patients have been treated with CMFlex™, an off-the-shelf 3D printed synthetic bone graft product developed and manufactured by Chicago-based Dimension Inx on the 3D-Bioplotter®.

Founded in 2017, Dimension Inx is a regenerative therapeutics company that designs, develops, and manufactures therapeutic products to restore tissue and organ function. The company owns four Desktop Health 3D-Bioplotters – two used for R&D and two used for manufacturing their commercial CMFlex product.

Dimension Inx received FDA clearance of CMFlex in December of 2022. CMFlex is currently available to a limited number of key surgeons with a broader release to follow later in 2024.

The first jaw cases were performed by Dr. Derek Steinbacher, Director of West River Surgery Center (Guilford, CT ), Former Professor Plastic surgery and Chief of Oral and Maxillofacial surgery at Yale New Haven Health, and Dr. Brian Farrell, DDS, MD, of the Carolinas Center for Oral & Facial Surgery (Charlotte, NC). Procedures performed included a mandibular angle augmentation (surgery of the lower jaw) and maxillary segmental osteotomy (surgery of the upper jaw).

CMFlex has also been used in dental socket preservation surgeries for future dental implant placement by Dr. Robert Bosack, DDS, Oral, Maxillofacial & Dental Implant Surgery (Orland Park, IL).

About CMFlex

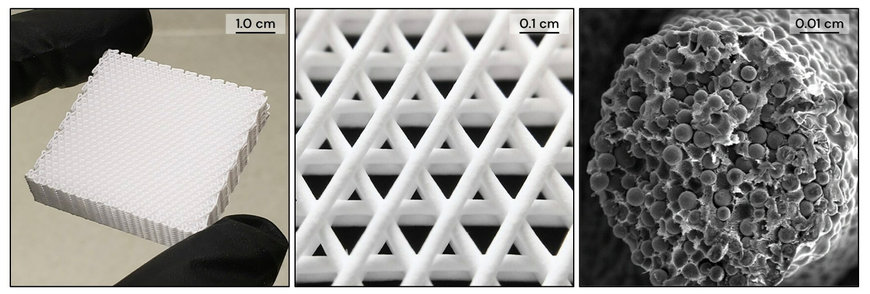

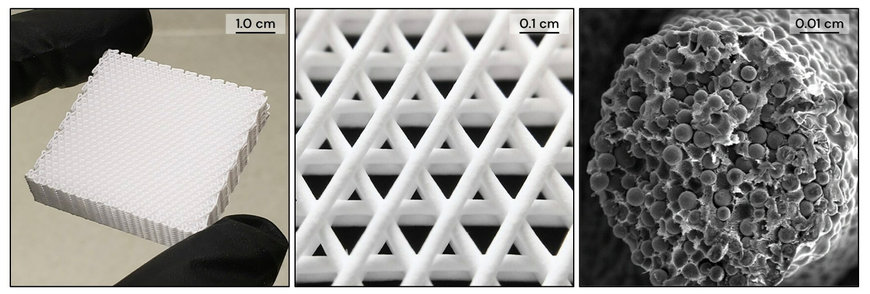

CMFlex is comprised primarily of hydroxyapatite, a naturally occurring mineral found in bone, combined with biodegradable polylactide-co-glycolide (PLG) polymer. Both materials have an extensive history demonstrating biocompatibility and clinical utility. Dimension Inx combines these base materials into a proprietary, microstructurally porous composite material, Hyperelastic Bone®, as first published in Science Translational Medicine in 2016.

Photo: Business Wire

This unique, easily deployable bone repair material is then 3D printed into CMFlex. which has an engineered architecture with nano, micro, and macro-level features designed to promote natural bone regeneration after implantation, without the need for an invasive autograft.

The resulting product is one that surgeons can size for each patient and is uniquely capable of absorbing fluid, which enables it to control bleeding during surgery while assisting the bone remodelling process once implanted.

The 3D-Bioplotter is a sophisticated extrusion-based 3D printer that processes liquids, melts, pastes, gels, or other materials, including cells, through a needle tip on a Swiss-made, 3-axis gantry system with high accuracy and repeatability, along with tight controls for temperature, sterility, and design. 3D-Bioplotter offers eight printheads with the widest range of temperatures in bioprinting – from 2°C to 500°C (35.6°F to 932°F) – enabling complex, multi-material medical parts.

Desktop Health announced the first patients have been treated with CMFlex™, an off-the-shelf 3D printed synthetic bone graft product developed and manufactured by Chicago-based Dimension Inx on the 3D-Bioplotter®.

Founded in 2017, Dimension Inx is a regenerative therapeutics company that designs, develops, and manufactures therapeutic products to restore tissue and organ function. The company owns four Desktop Health 3D-Bioplotters – two used for R&D and two used for manufacturing their commercial CMFlex product.

Dimension Inx received FDA clearance of CMFlex in December of 2022. CMFlex is currently available to a limited number of key surgeons with a broader release to follow later in 2024.

The first jaw cases were performed by Dr. Derek Steinbacher, Director of West River Surgery Center (Guilford, CT ), Former Professor Plastic surgery and Chief of Oral and Maxillofacial surgery at Yale New Haven Health, and Dr. Brian Farrell, DDS, MD, of the Carolinas Center for Oral & Facial Surgery (Charlotte, NC). Procedures performed included a mandibular angle augmentation (surgery of the lower jaw) and maxillary segmental osteotomy (surgery of the upper jaw).

CMFlex has also been used in dental socket preservation surgeries for future dental implant placement by Dr. Robert Bosack, DDS, Oral, Maxillofacial & Dental Implant Surgery (Orland Park, IL).

About CMFlex

CMFlex is comprised primarily of hydroxyapatite, a naturally occurring mineral found in bone, combined with biodegradable polylactide-co-glycolide (PLG) polymer. Both materials have an extensive history demonstrating biocompatibility and clinical utility. Dimension Inx combines these base materials into a proprietary, microstructurally porous composite material, Hyperelastic Bone®, as first published in Science Translational Medicine in 2016.

Photo: Business Wire

This unique, easily deployable bone repair material is then 3D printed into CMFlex. which has an engineered architecture with nano, micro, and macro-level features designed to promote natural bone regeneration after implantation, without the need for an invasive autograft.

The resulting product is one that surgeons can size for each patient and is uniquely capable of absorbing fluid, which enables it to control bleeding during surgery while assisting the bone remodelling process once implanted.

The 3D-Bioplotter is a sophisticated extrusion-based 3D printer that processes liquids, melts, pastes, gels, or other materials, including cells, through a needle tip on a Swiss-made, 3-axis gantry system with high accuracy and repeatability, along with tight controls for temperature, sterility, and design. 3D-Bioplotter offers eight printheads with the widest range of temperatures in bioprinting – from 2°C to 500°C (35.6°F to 932°F) – enabling complex, multi-material medical parts.

www.desktopmetal.com