www.medical-devices.tech

04

'21

Written on Modified on

Teledyne FLIR

Biomedical Imaging: Guide to Choosing Machine Vision Camera Specifications and How to Calculate Them

Application Specific Factors to Consider

Resolution and color accuracy

The resolution required is dependent on the magnification of the structure of interest in the sample relative to the size of pixels on the camera; i.e. high resolution in a microscopy application can be achieved by a 2MP camera, a 25MP camera, or anything in between. It depends on the magnification of the structure of interest in the sample by the optics relative to the size of the pixels on the camera. In order to select the best camera options to achieve the desired resolution, first determine the size of the smallest structure in the sample that you wish to resolve. Then, multiply it by the lens magnifications in your optical system. This will provide the size of these structures when projected on the camera sensor.

If the size of the structure is at least 2.33 (Nyquist) times the size of a pixel on the camera sensor, then the camera should be able to resolve that structure. For example, if the size of these projected structures is ~8um, then a camera with 3.45um pixels should be able to resolve those structures. There are other methods to measure resolution (e.g. line pairs) but this is an easy calculation to find suitable camera options to test.

Imaging applications such as histology, cytology, and cytogenetics work with a broad range of white light (between ~400 nm and 700 nm) or use a selected wavelength within this range (for example, 565 nm). If the specimens in these samples are not alive (or fixed) they can be exposed to bright light levels without the risk of the stain fading or killing the sample. Under these conditions, the main requirement for the camera is high resolution and color reproduction. In other words, low light sensitivity is not an important factor. To find high-resolution models, use our FLIR Machine Vision Camera Selector and filter and sort for megapixels.

Sensitivity, Quantum Efficiency, and Dynamic Range

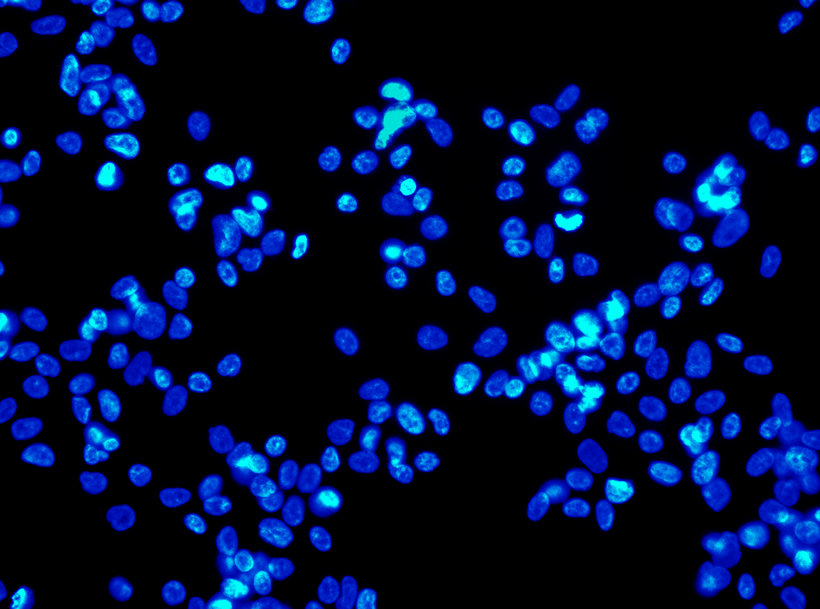

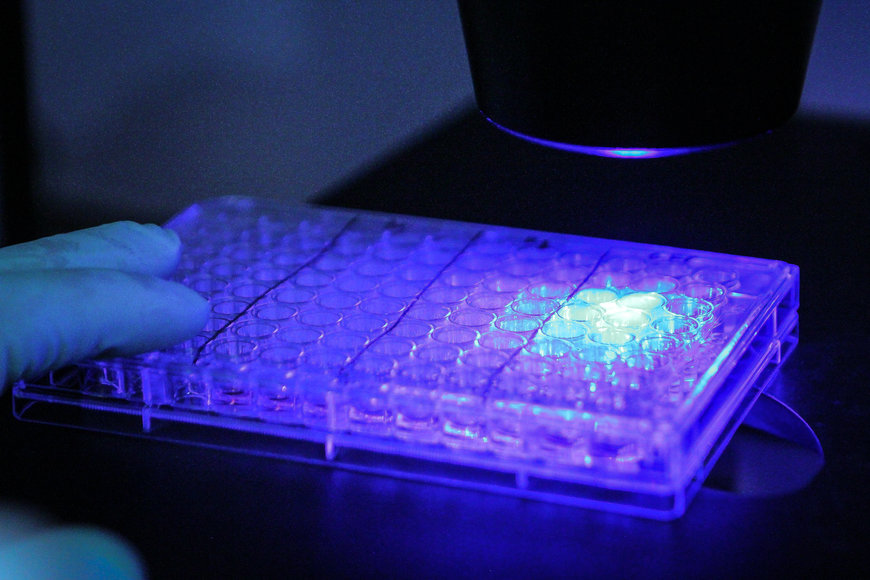

For imaging applications with live specimens, the challenge is to avoid overexposing the sample to too much light, which will bleach fluorescent molecules or kill the specimen. These applications typically use a technique called epifluorescence. Epifluorescence techniques can be used on both fixed and live specimens. Some specimens are rare or costly to acquire and the process for creating samples can be expensive in materials and labor.Therefore, a system that preserves the quality of the samples can help to reduce the ongoing cost of these imaging applications.

Epifluorescence uses a high energy wavelength that is filtered to excite the sample to emit a low energy wavelength. The low energy wavelength is filtered back to the camera. Under these conditions, the main requirement is sensitivity because this allows the use of less intense, damaging light on the sample. A camera with excellent sensitivity can provide high quality images even when the emission light is low energy.

To find models with excellent sensitivity to perform well under low light conditions, you can focus on three specifications: absolute sensitivity, quantum efficiency, and dynamic range. Absolute sensitivity is the number of photons needed to get a signal equivalent to the noise observed by the sensor, the lower the number the better. Quantum efficiency is the percentage of photons converted to electrons at a particular wavelength—here you want a high number. Dynamic range is the ratio of signal to noise including temporal dark noise (the noise in the sensor when there is no signal), the higher the better. For easy comparison, use the FLIR model selector to filter and find the highest values.

Generally, monochrome models have better performance in low light compared to color equivalents. To view the details of a model’s imaging performance, look at detailed EMVA Imaging Performance document for the model. On the FLIR website, these can be found on “Camera Resources” link for each camera family: Blackfly S GigE Resources, Firefly Resources.

For more information on the EMVA imaging performance standard and how to compare models for sensitivity, see How to Evaluate Camera Sensitivity.

Combination of Factors

For applications that use both white light and epifluorescence, look for camera models that offer Sony’s new conversion gain feature, which provides the ability to optimize the sensor for high sensitivity or high saturation capacity. High conversion gain is ideal for low light environments, as read noise is minimized, yielding a low Absolute Sensitivity threshold perfect for detecting weak signals with short exposures. Low conversion gain is ideal for brightly lit conditions, as saturation capacity is maximized, yielding improved dynamic range. The maximum dynamic range will be limited by the 12-bit ADC.

To find a list of models with conversation gain, please refer to our get in touch with one of our machine vision experts.

Choosing the right cameras

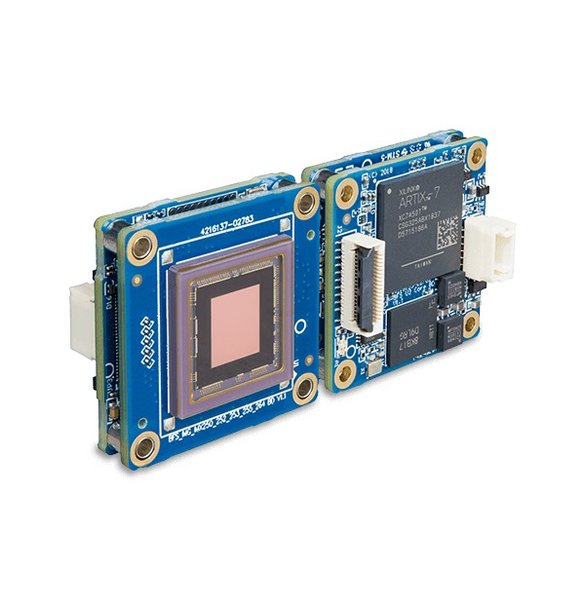

When choosing a camera, selecting a newer CMOS sensor is always a good starting point. Newer sensors typically offer greater performance (and may be lower in price). Also, if the application in question requires the purchase of many cameras over several years (for example, the ongoing manufacture of a diagnostic instrument), then it is critical to select a camera that is not at the end of its lifecycle—otherwise you will have to incur the cost of designing-in a replacement camera prematurely.

FLIR manufactures over 200 variants of machine vision cameras that broadly fit into three camera families that use the latest CMOS sensors: Blackfly S, Oryx, and Firefly.

The Blackfly S camera family offers the broadest range of sensors, form factors, and interfaces. With every model offered in both GigE variants, these cameras are extremely versatile and easy to incorporate during the design-in phase. Board level Blackfly S versions are miniaturized versions of our full featured cased variety and are particularly suited for space constrained and embedded applications. The wide range of features, great price to performance ratios, and resolutions up to 24MP makes them a preferred choice in biomedical and life science applications.

The Oryx camera family offers high resolution sensors paired with the fast 10GigE interface, enabling the capture of 4K resolution, 12-bit images at over 60FPS. Oryx’s 10GBASE-T interface is a proven and widely deployed standard that provides reliable image transfer at cable lengths over 50 meters on inexpensive CAT6A, or greater than 30 m on CAT5e.

The Firefly camera family offers a very small case form factor, light weight, low power, and low price. The Firefly DL model also has the capability to run a previously trained neural network that can be used for object detection or classification.

All FLIR machine vision color cameras provide the ability to customize color reproduction in the form of different white balancing options and the use of a unique color correction matrix, which is important in biomedical imaging where accuracy of colors can mean different things depending on visual human analysis for diagnosis vs. a machine readable format for data accuracy. For more information on these features, see Using sing Color Correction in Blackfly S and Oryx.

Additionally, the FLIR machine vision Blackfly S, Oryx, and Firefly camera families can be controlled and programmed using GenICam3 and the Spinnaker SDK which has been designed ground-up with ease of development and deployment in mind, ensuring we enable faster application development and testing.

To further narrow down the selection of camera models, the FLIR website has a machine vision camera selector with multiple filter criteria available:

VIEW MACHINE VISION CAMERA SELECTOR

Need help? Have additional questions? Our machine vision experts are happy to help you select the right camera for your specific needs: click here to get in touch.